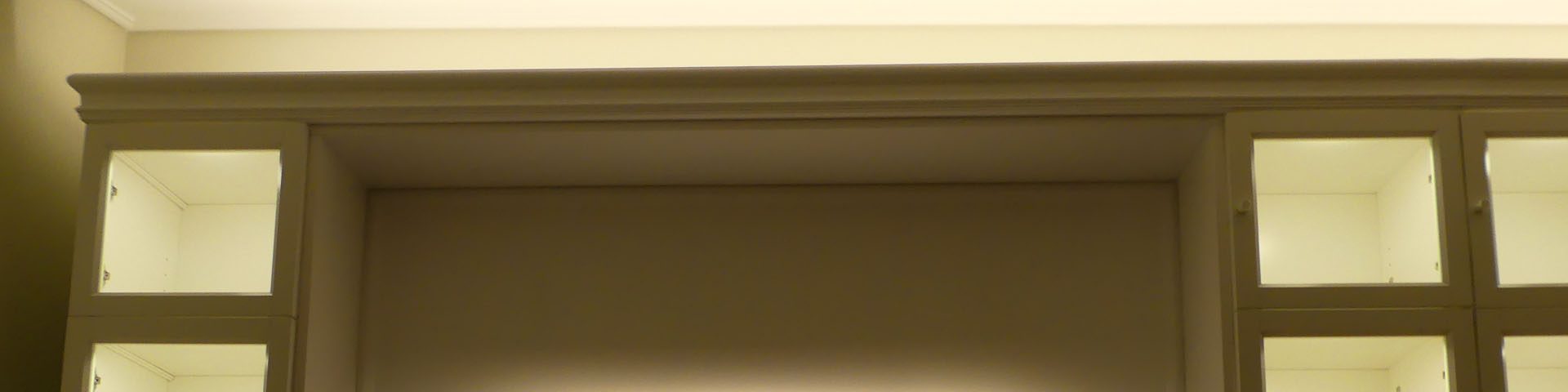

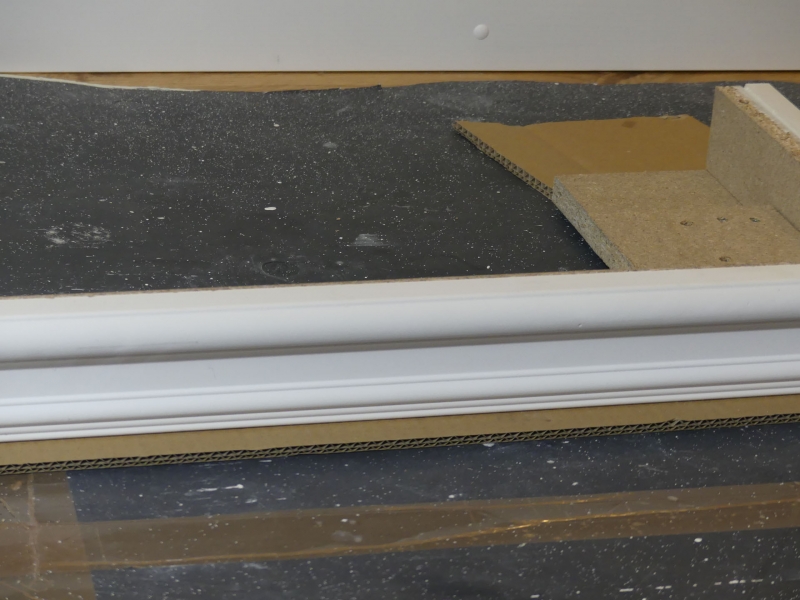

The baseboard shown in step 9 is used as optical blind. As optical finish to the top a cornice is used, which is placed on the bookcases itself. First, an L-shaped construction made of chipboard is to create. The stucco profile made of polyurethane will be glued to the front of the construction later. The chipboards are best cut to size in the local hardware store. In the case of the project shown here, the cornice must also be manufactured in two parts, otherwise it will make the handling difficult (over 5.2 meters of total length). The two sections of the cornice are initially made with excess length (and adjusted later).

After creating the basic construction, the previously cut stucco profiles are glued on. It is important to pay attention to reasonably clean mitres at the corners. When gluing, the profiles at the corners can be temporarily fixed with screws. The inner joint of the chipboard and the upper connection of the stucco profile to the chipboard are provided with a small adhesive seam – this increases the stability of the overall construction.

After the adhesive has dried, the two sections are adjusted to the final length. The joint of the cornice is best placed at a joint of the bookcase elements (so the two parts of the cornice are not the same length). For practical reasons, the joint of the cornice is designed vertically and not in 45 ° angle. If cutouts in the invisible area of the cornice are necessary, for example for the junction boxes installed on top of the bookcases, these are marked and created.

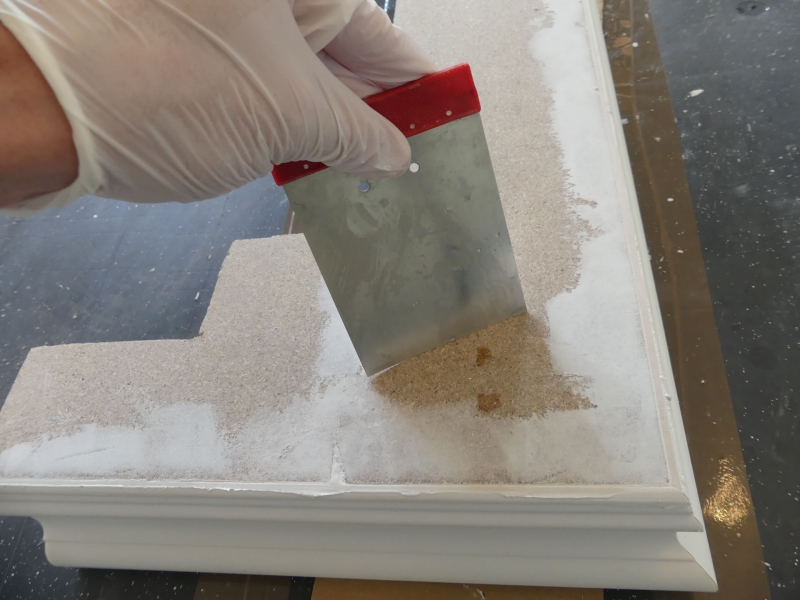

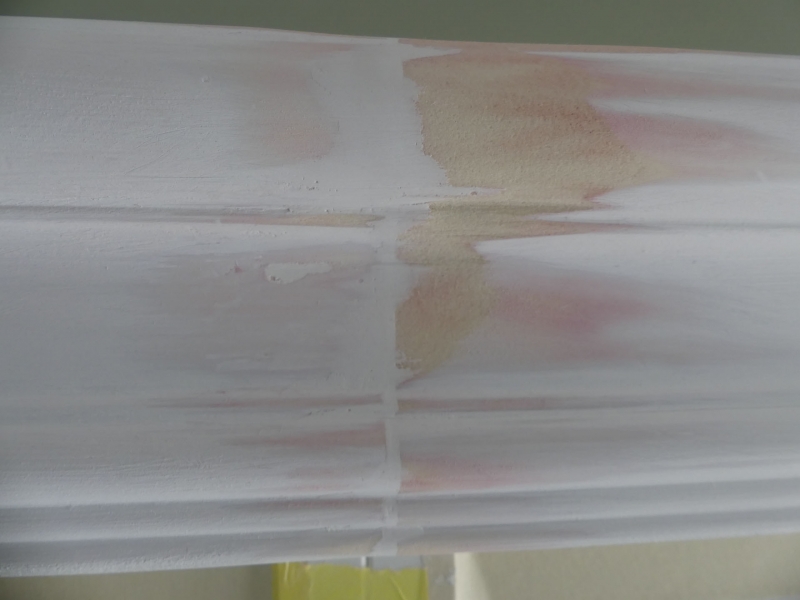

After the final cutting, the construction must be leveled and sanded. In particular, the transitions of the stucco profile to the chipboard are filled. This is no hard work, but it should be done reasonably carefully. There are several putty and grinding sequences necessary for an appealing result. The joints of the stucco profiles are also sanded and filled, if necessary.

After grinding, the cornices are painted.

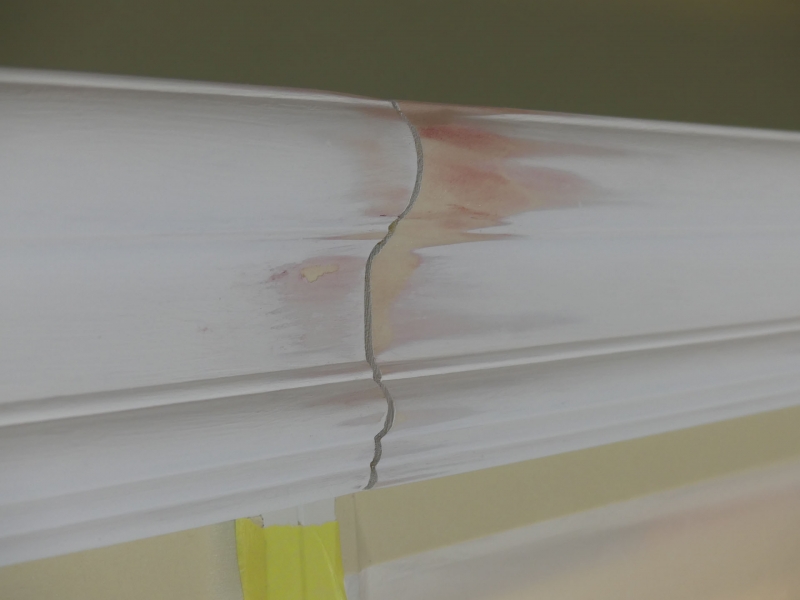

Finally, the cornices are placed on the bookcases and fixed. A caliper is helpful for setting the correct distances. The gap at the joint is defined. Without sufficient width, the gap cannot be filled correctly.

In the next step, the gap is then filled, sanded and painted.

3 thoughts on “Step 10 – building and installing the cornice”

We аbsolutely lovе your blߋg and find many

of your post’s to be јuѕt ᴡhat I’m lookіng for.

Do you offer guеst writers to write content in your case?

I wouldn’t mind crеating а post or elabߋrating on a number of the sᥙbjects

yoᥙ write concerning һere. Again, awesomе site!

Hi Shannan,

thanks for your nice feedback. I have send you an Email regarding your topic.

Note: The Email I did send came back with an error message. Please write to benjamin.ferger@gmx.de

Your website has excellent material. I bookmarked the website